Welcome to ISTT

Webinar — 2024-05-08

Greenhouse Gas Emission Calculation of Trenchless Technologies

Category: Environmental Issues

Presenter: Heikki Aakko

Presenter: Heikki Aakko

Date: 8 May 2024

Organization: Gidon Infra Oy

Time: 10:00 US EST, 16:00 CEST

URL: click here

Click to get access to video (Members Only)

Click to get access to video (Members Only)

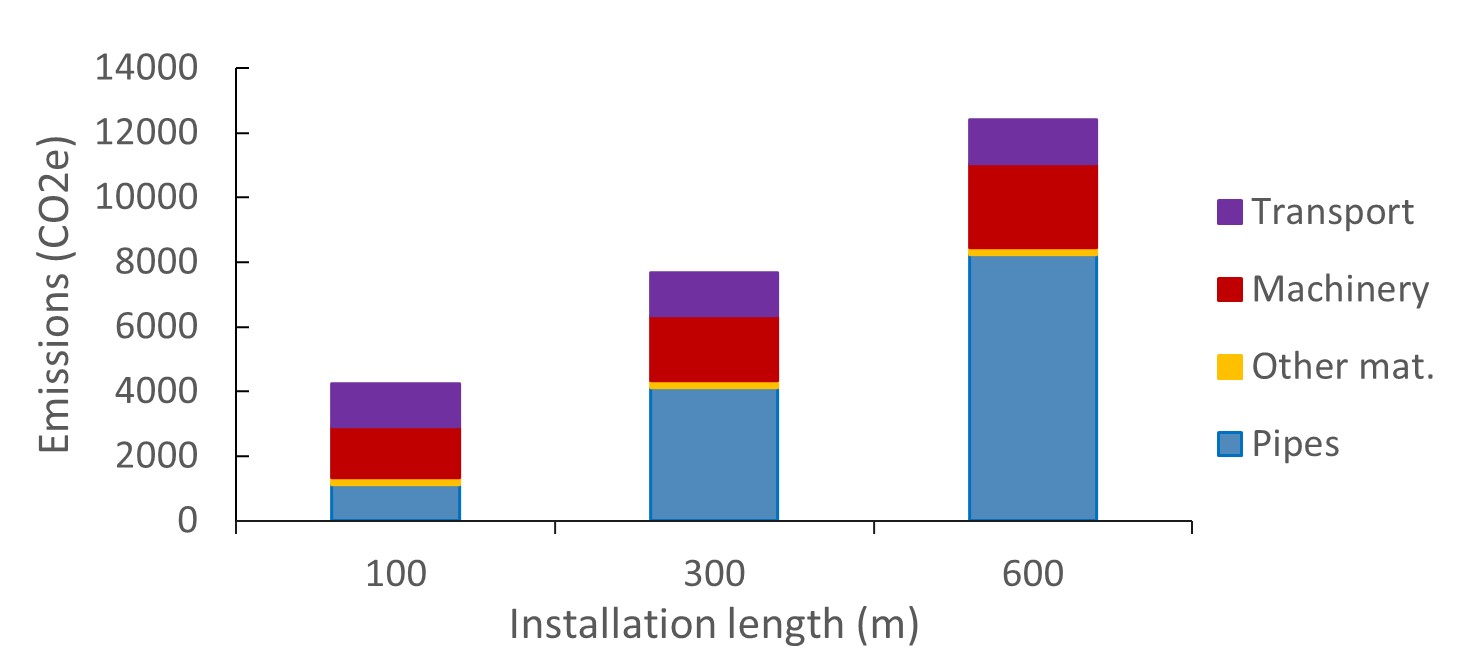

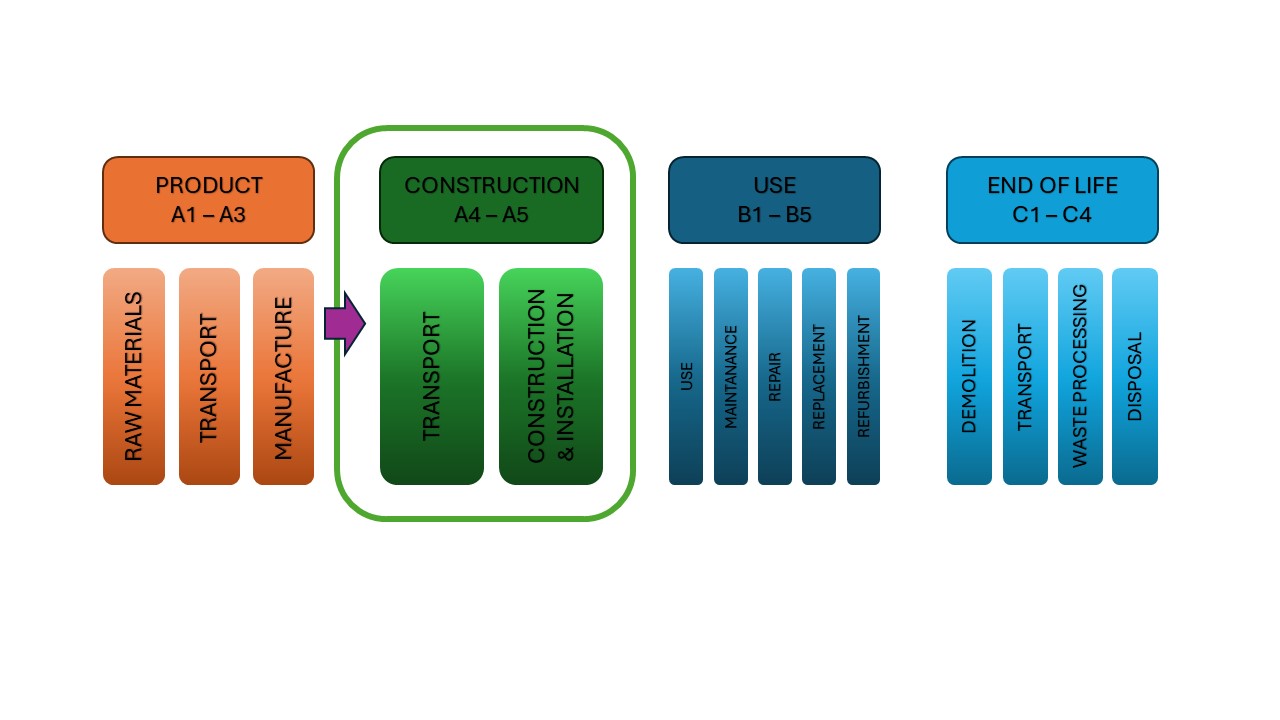

In the webinar, I’ll give a short summary of my thesis, explaining the general principles used to develop the theoretical framework for calculating and estimating emissions of different trenchless techniques in carbon dioxide equivalent (CO2e). Although the calculator itself is not publicly available, I will go through the general ideas of how the calculator was constructed, what kind of challenges there were building it, and what other observations were made. I will explain the relevance of my thesis and its need and the key objectives, like transparency, credibility, and adaptability. It is important to understand all the relevant variables and acknowledge which factors are not accounted for. Some calculation examples from the thesis will be presented, and what can be concluded based on the results and which questions still need further research. The outcome from the sensitivity analysis part of my thesis will be explained, i.e., how changes in variables affect the results. Finally, I will summarize all the key takeaways from my thesis, explain the conclusions on what should be done in the future, what can be done based on my thesis, and what can be done to lower CO2e emissions when it comes to trenchless technologies.

About Heikki Aakko

Heikki Aakko is a project engineer at Gidon Infra Oy, a Finland-based independent design and consulting office specializing in trenchless solutions. He has experience in projects ranging from preliminary studies to assisting with the tender process, tailored to customer needs. He holds a master’s degree in environmental engineering from the University of Oulu, specializing in water and environment. He has a background in water and wastewater network design and site supervising experience. His thesis on the emission calculation of trenchless technologies was published in December 2023. He is passionate about learning and spreading the knowledge of trenchless technologies with a sharp focus on sustainability.

Read More... Cart

Cart