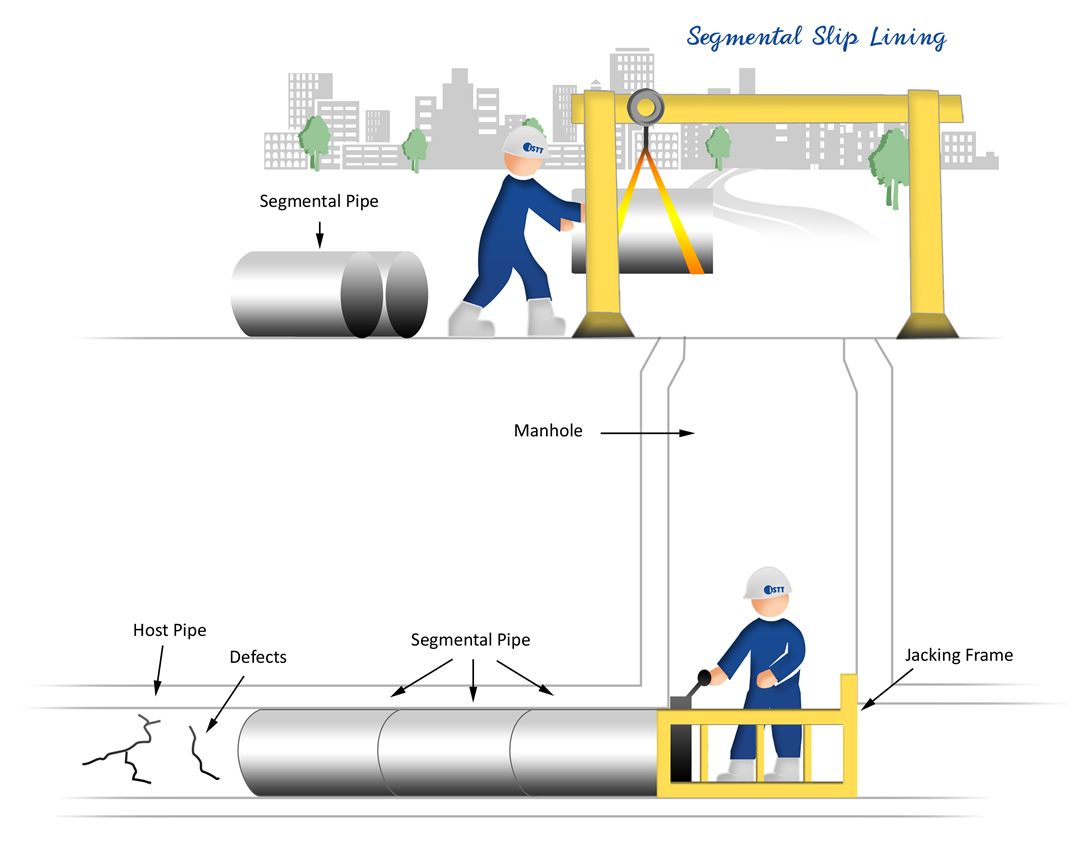

With Pipe Segments

See “replacement slip lining” for a general description of the method. In gravity sewer rehabilitation applications, an important advantage of this form of slip lining is that the new pipe can be inserted in segments within the host pipe during active sewer flow – thus avoiding the need for bypass operations that may be necessary with various other rehabilitation techniques.

Segmental slip lining is typically used to insert Glass Reinforced Plastic (GRP) pipes into circular and non-circular pipes. The size of the host pipe can range from small non-man entry to larger man entry pipes. Segmental liners may be pushed into the host pipe by hydraulic power or winched in place. Concrete and steel pipe with higher compressive strength and stiffness may also be installed as slip liners and present fewer engineering challenges than plastic pipes during grouting.