Past Webinars

To see the past webinars and/or powerpoints, please login from the top-right corner.

2024-07-02 Webinar

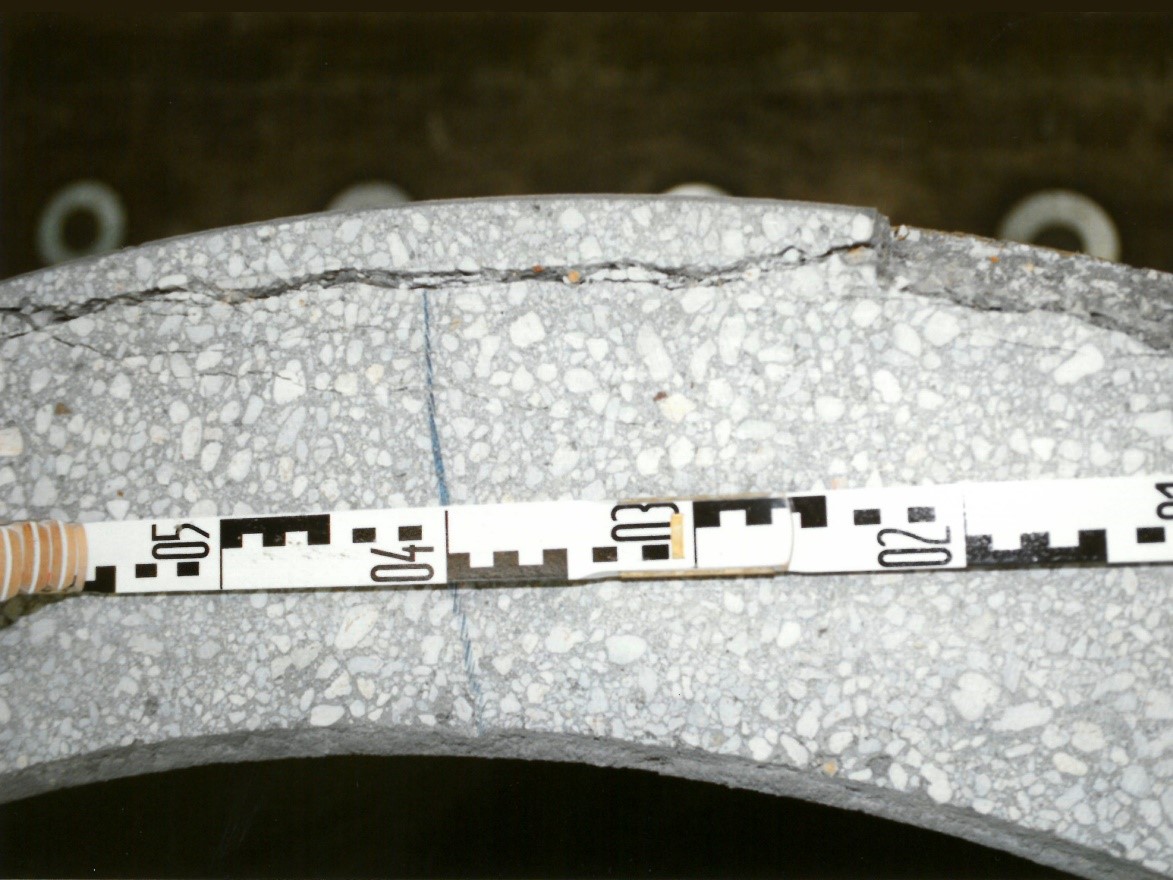

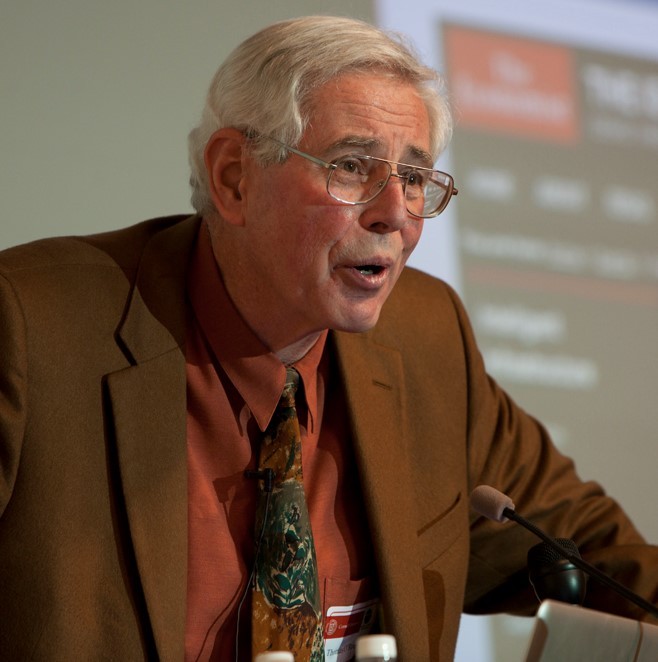

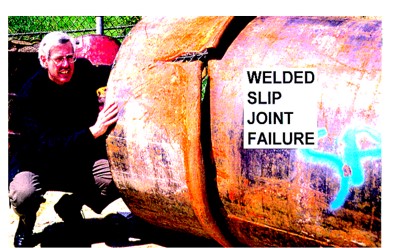

Damage, Causes, and Consequences of Damage during Utility Tunneling

Category: Pipe Jacking

Presenter: Dr.-Ing. Robert Stein

Presenter: Dr.-Ing. Robert Stein

Date: 2 July 2024

Organization: Stein & Partner GmbH/STEIN Ingenieure GmbH, Germany

Click to get access to video (Members Only)

Click to get access to video (Members Only)

Utility Tunnelling, which includes pipe jacking and microtunnelling, is becoming the predominant construction method for drainage pipelines in metropolitan areas worldwide. With this rise in popularity comes the demand for ever more challenging projects. Put simply, utility tunneling projects are reaching ever greater depths and lengths. In addition, there is a demand for driving curves, S-curves, and even multiple space curves within a single section to optimize the route and increase the cost-effectiveness of pipe jacking. This shift in application limits also increases the risk of execution errors during utility tunneling. This webinar, therefore, presents possible damage, causes, and consequences of damage during pipe jacking and microtunnelling, thus providing important engineering know-how to ensure damage-free Utility Tunnelling even under more demanding boundary conditions. Specifically, damage, causes, and consequences of leaking pipe connections, cracks, spalling, position changes of the jacking pipes, and damage to jacking components are addressed.

About Dr.-Ing. Robert Stein

Dr.-Ing. Robert Stein is the Managing Associate of Prof. Dr.-Ing. Stein & Partner GmbH and Managing Director of STEIN Ingenieure GmbH and STEIN Infrastructure Management GmbH. He has been involved with a multitude of utility tunnelling projects. Most notably, as the project manager responsible for the approval process, planning, supervision and quality control of the 52 km long, DN 1400 - DN 2800, deep tunnel sewage system “Emscher Kanal”for the federal state of North Rhine-Westphalia. For the construction of the gas pipeline Nord Stream running through the Baltic Sea, he was in charge of the feasibility study for a trenchless connection of the pipeline in the area of the Greifswalder Bodden on behalf of Nord Stream AG, Switzerland. Since 1995, he has published more than 100 publications, reports, expertise, and feasibility studies. He is the author of the reference book“Wertermittlung von Abwassernetzen (Asset Valuation of Sewer Networks),” Trenchless Technology for Installation of Cables and Pipelines – 2nd Volume: Horizontal Directional Drilling (HDD), of the chapter on pipe jacking works (ATV DIN 18319) and co-author of the 4th edition of the international bestseller “Instandhaltung von Kanalisationen” (Rehabilitation of Drain and Sewer Systems) as well as of various technical articles.

Read More...2024-05-07 Webinar

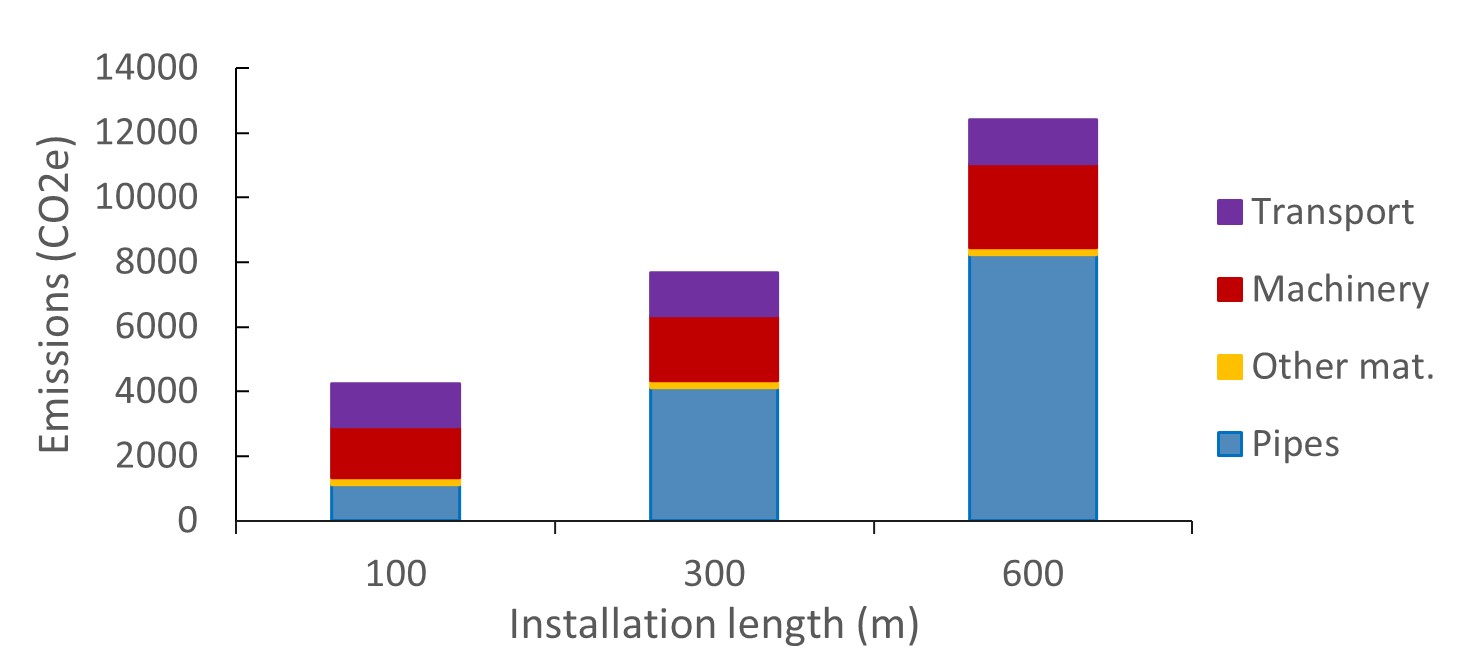

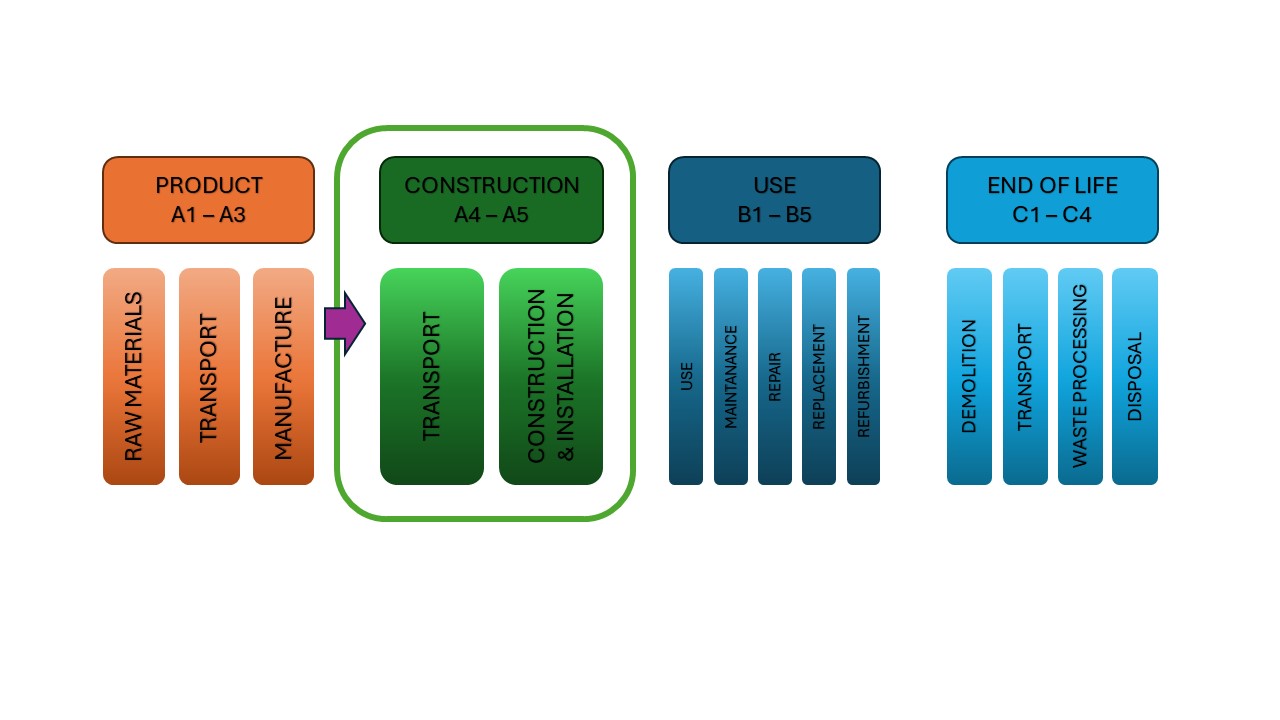

Greenhouse Gas Emission Calculation of Trenchless Technologies

Category: Environmental Issues

Presenter: Heikki Aakko

Presenter: Heikki Aakko

Date: 7 May 2024

Organization: Gidon Infra Oy

Click to get access to video (Members Only)

Click to get access to video (Members Only)

In the webinar, I’ll give a short summary of my thesis, explaining the general principles used to develop the theoretical framework for calculating and estimating emissions of different trenchless techniques in carbon dioxide equivalent (CO2e). Although the calculator itself is not publicly available, I will go through the general ideas of how the calculator was constructed, what kind of challenges there were building it, and what other observations were made. I will explain the relevance of my thesis and its need and the key objectives, like transparency, credibility, and adaptability. It is important to understand all the relevant variables and acknowledge which factors are not accounted for. Some calculation examples from the thesis will be presented, and what can be concluded based on the results and which questions still need further research. The outcome from the sensitivity analysis part of my thesis will be explained, i.e., how changes in variables affect the results. Finally, I will summarize all the key takeaways from my thesis, explain the conclusions on what should be done in the future, what can be done based on my thesis, and what can be done to lower CO2e emissions when it comes to trenchless technologies.

About Heikki Aakko

Heikki Aakko is a project engineer at Gidon Infra Oy, a Finland-based independent design and consulting office specializing in trenchless solutions. He has experience in projects ranging from preliminary studies to assisting with the tender process, tailored to customer needs. He holds a master’s degree in environmental engineering from the University of Oulu, specializing in water and environment. He has a background in water and wastewater network design and site supervising experience. His thesis on the emission calculation of trenchless technologies was published in December 2023. He is passionate about learning and spreading the knowledge of trenchless technologies with a sharp focus on sustainability.

Read More...2024-02-08 Webinar

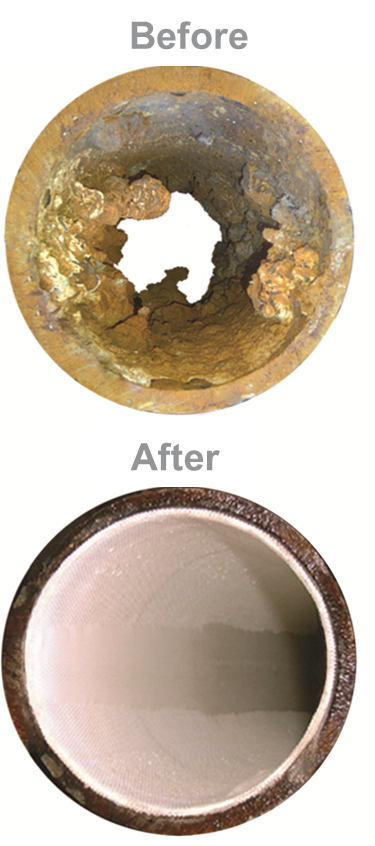

Resilient and Structural Trenchless Watermain Pipe Renewal Technology

Category: Pipe rehabilitation

Presenter: Martin Bureau

Presenter: Martin Bureau

Date: 8 February 2024

Organization: ALTRA SANEXEN

Click to get access to video (Members Only)

Click to get access to video (Members Only)

This webinar presents the results of a seismic resiliency evaluation program of a structural Cured-in-Place Pipe (CIPP) AWWA-Class IV watermain renewal technology, which was used for deteriorated legacy water main renewal and strengthening against earthquake and natural hazard effects. This CIPP product is a composite lining consisting of an inner and outer layer or jacket, produced by circular weaving of continuous textile yarns, impregnated with an epoxy. This product is used to renew water mains by insertion at access pits, without the need for complete excavation of the pipe to be replaced. To this date, more than 2 400 km of watermains, mainly in North America, have been renewed with this technology.

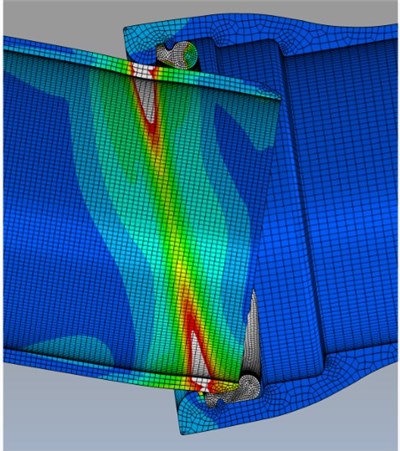

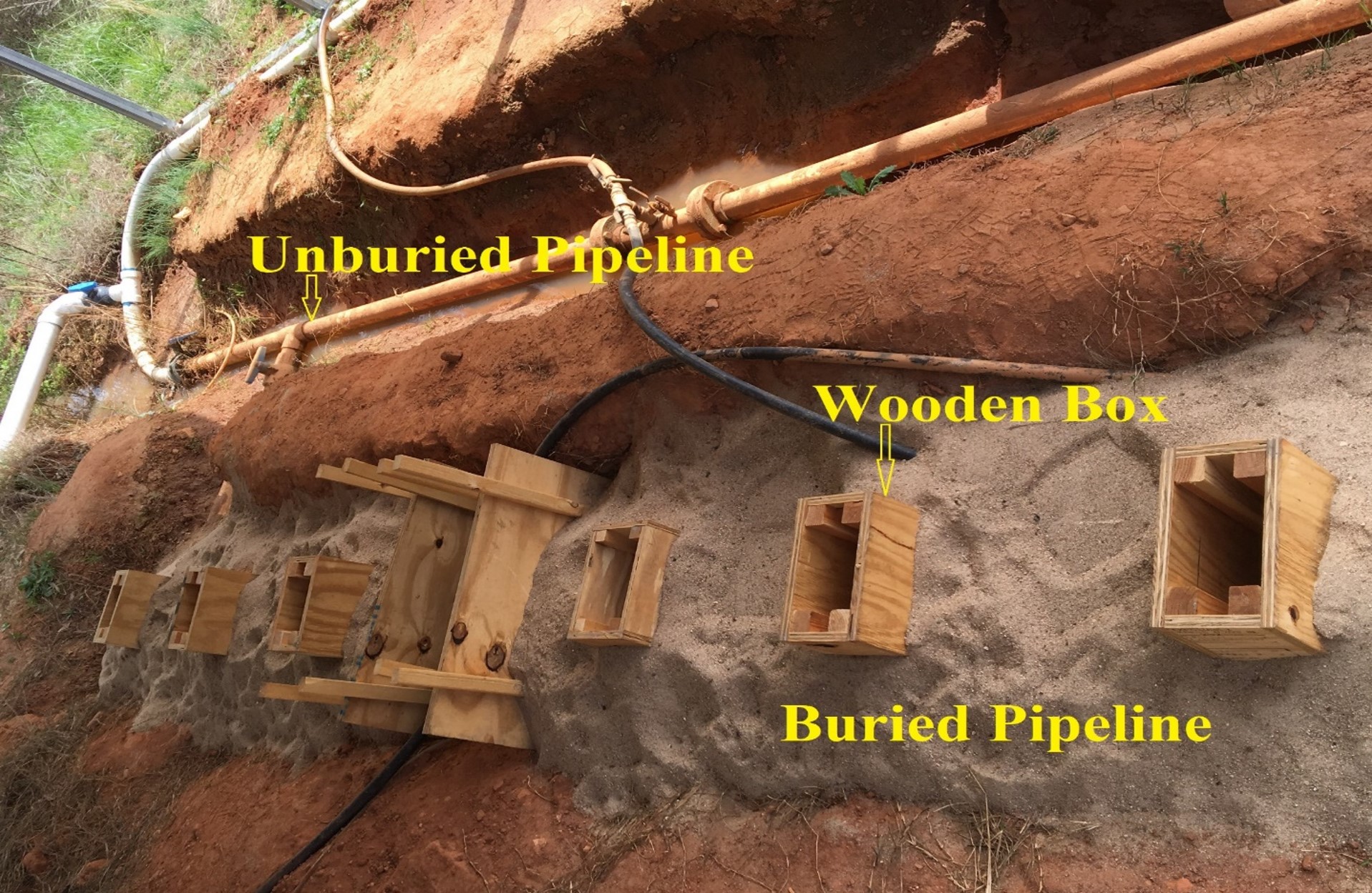

The product was evaluated at Cornell University’s Large-Scale Lifelines Laboratory, through a large-scale fault rupture test during which the CIPP-lined ductile iron (DI) watermain, comprising five pipe sections, was progressively subjected to very large tensile and bending loads, first resulting in the watermain failure due to joint opening, until debonding and full detachment of the CIPP from the watermain, leading to extensive extension and bending of the CIPP. Debonding loads of at least 120 kN were measured during testing. Throughout the test, the lined watermain was able to accommodate significant fault movement through axial pullout and rotation of the joints, including a maximum 0.77 m of axial extension (average tensile strain of 6.2%) and lateral offset by 14°-rotation of the two joints closest to the fault. Despite such large deformations the CIPP remained structurally sound and retained water pressure as no water leakage was observed. Post-fault-rupture testing of the liner indicated that residual mechanical properties were similar to pristine liner properties.

Fault rupture simulated in the large-scale test was deemed representative of the most severe ground deformation that occurs along the margins of liquefaction-induced lateral spreads and landslides.

Picture left: Lined Pipes Before and After / Picture right: Unburied Lined Pipeline after Fault Rupture Test in Split Basin Test

About Martin Bureau

Dr Martin Bureau began his career in Engineering in 1992, with a Bachelor of Engineering in Metallurgy, followed by a Master’s degree in Physical Metallurgy, and a Doctorate in Materials Science. He worked in applied research at the National Research Council of Canada (NRC). He has authored more than 200 scientific journal articles and international conference reviews, and is co-author of more than 40 patents.

Today, he and his team are spearheading Sanexen’s exciting and innovative technology, ALTRA Proven Solutions, tackling the most important water challenges facing cities across North America.

Read More...2023-12-12 Webinar

Key findings from a comparison of pressure sewer rehabilitation technologies

Category: Rehabilitation

Presenter: Iain Naismith

Presenter: Iain Naismith

Date: 12 December 2023

Organization: IKT Institute

Click to get access to video (Members Only)

Click to get access to video (Members Only)

Iain Naismith and Markus Gillar of IKT will present and answer questions on the findings from a comparative evaluation of six systems for rehabilitating pressure sewers. This three-year, 1:1 scale project was undertaken on behalf of a group of German sewer network owners to help them understand the capabilities and limitations of a selection of available technologies for rehabilitating pressure sewers using Class A, fully structural liners. Two close-fit and four cured-in-place-liners were examined and the findings have been used to advise network owners on quality assurance measures they need to consider when embarking on pressure sewer re-lining projects.

About: Dr. Iain Naismith

Dr Iain Naismith is a Senior Research Fellow at IKT with 35 years of experience in environmental, water and sewerage-related research. Based in the UK, he has a particular focus on international projects and knowledge sharing for this not-for-profit engineering research institute. He has been involved in the evaluation of performance of sewerage repair and rehabilitation products and products in contact with drinking water for some 20 years.

2023-08-28 Webinar

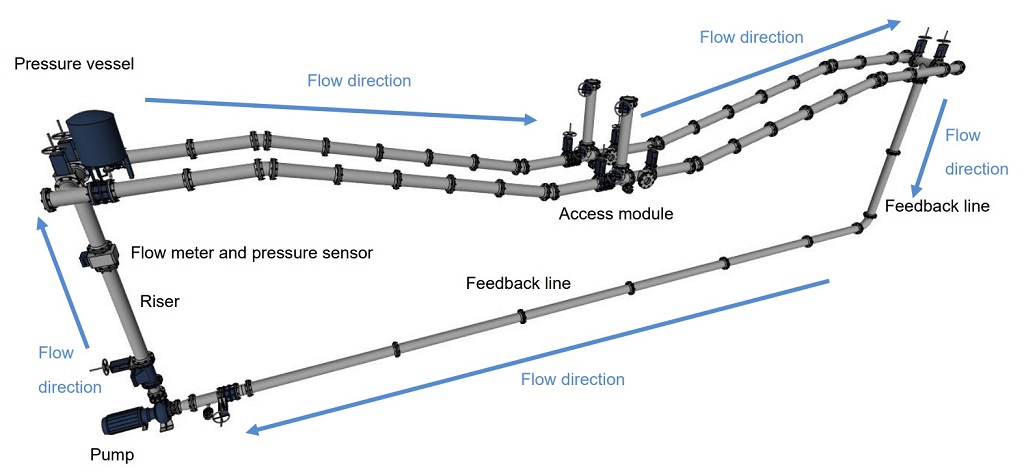

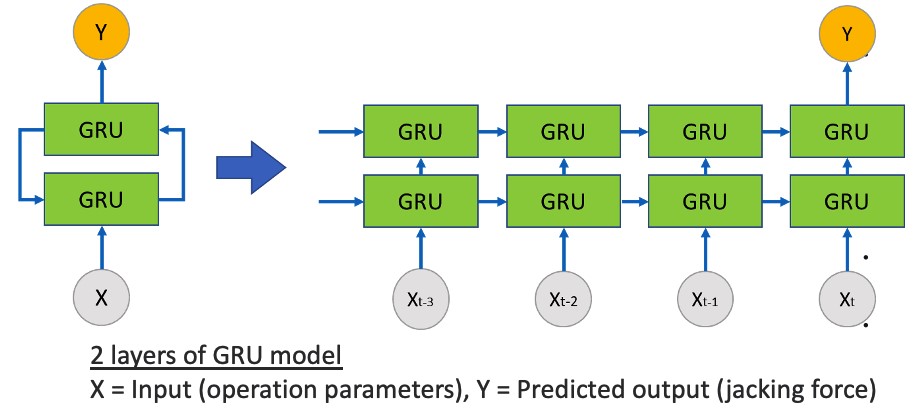

Evaluation of jacking forces in weathered geology: geomaterial characterization and deep learning techniques

Category: Pipe jacking

Presenter: Dr. Chung Siung Choo

Presenter: Dr. Chung Siung Choo

Date: 28 August 2023

Organization: University of Technology, Sarawak Campus

Click to get access to video (Members Only)

Click to get access to video (Members Only)

Overview

The webinar focuses on the evaluation of frictional jacking forces for drives traversing fractured and weathered 'soft rocks'. Some methods are presented for deriving equivalent rock strength parameters for the prediction of frictional jacking forces, including shear box testing on tunnelling rock spoil and in situ pressuremeter testing. However, existing frictional models are dependent on the strength parameters of the traversed geomaterials, with minimal focus on the significance of pipe jacking operation parameters. Case studies are presented, showing the application of deep learning techniques for visualising the influence of various operation parameters on jacking forces.

About Dr. Chung Siung Choo

Choo is currently a Senior Lecturer at Swinburne University of Technology, Sarawak Campus. He has 12 years of working in both academia and industry. He obtained his BEng (Civil) (Honours) in 2010. Subsequently, he went on to complete his PhD, producing a thesis titled 'Development and assessment of equivalent rock strength parameters for the back-analysis of pipe-jacking forces'. Since then, he has contributed articles in various journals, including Journal of Geotechnical and Geoenvironmental Engineering, Engineering Geology, and Tunnelling and Underground Space Technology. He currently serves as a committee member for the Malaysian Association for Trenchless Technology (MATT).

Read More...2023-07-18 Webinar

Direct Steerable Pipe Thrusting DSPT (also known as Direct Pipe ®)

Category: Direct Steerable Pipe Thrusting (DSTP)

Presenter: Kimberlie Staheli, Ph.D., P.E.

Presenter: Kimberlie Staheli, Ph.D., P.E.

Date: 18 July 2023

Organization: Staheli Trenchless Consultants, Inc.

Click to get access to video (Members Only)

Click to get access to video (Members Only)

Direct Steerable Pipe Thrusting (DSPT) is the generic name for the installing a steel pipeline using the following features: 1) a microtunneling machine is used for excavation; 2) the pipe is installed using a pipe thruster 3) the pipe is typically installed along a designed bore path that includes curves similar to typical HDD designs. Herrenknecht Corporation was the first manufacturer to bring this technology to the market with their Direct Pipe® system with the first installation occurring in 2007. Since that time, the application of DSPT has been steadily increasing with hundreds of installations completed worldwide. DSPT is often described as a combination of horizontal directional drilling (HDD) and Microtunneling (MT) as DSPT has operational and behavioral characteristics that are similar to microtunneling while allowing the installation of pipelines with geometric characteristics that are similar to HDD installations. However, understanding the features of DSPT and how they compare to microtunneling and HDD is critical to determine and analyze the mechanisms that govern the development of thrust forces, the risk of inadvertent returns, and the behavior of the pipe within the borehole.

About Kimberlie Staheli, Ph.D., P.E.

Dr. Staheli is the President and Founder of Staheli Trenchless Consultants, Inc. located in Seattle, Washington, USA. Staheli Trenchless specializes in the design and construction management of trenchless projects around the world. Kimberlie has a degree in Mechanical Engineering from Rensselaer Polytechnic Institute, a master’s in civil engineering from Mississippi State University, and a Ph.D. in geotechnical engineering from Georgia Institute of Technology. Kim’s passion is managing risks on trenchless projects and educating the industry to allow for more successful trenchless installations. Dr. Staheli has published over 100 technical papers on Trenchless Technology. Dr. Staheli is a Past Chair of the North American Society for Trenchless Technology, and the current Vice Chair of the International Society for Trenchless Technology.

Read More...2023-05-12 Webinar

Hazard Resilient Infrastructure and Lessons from the Turkey-Syria Earthquake

Category: Analytical models for the soil-structure interaction

Presenter: Tom O'Rourke

Presenter: Tom O'Rourke

Date: 12 May 2023

Organization: Cornell University

Click to get access to video (Members Only)

Click to get access to video (Members Only)

Non-Members can join our webinars (no fee required) but recorded videos and Presentation files are for ISTT members only (after member login). No certificates will be issued.

Resilient underground infrastructure can accommodate large ground deformation from earthquakes, hurricanes, floods, adjacent construction, and subsidence. Professor O’Rourke will describe how ten new pipeline and conduit systems have been developed and commercialized using a protocol of large-scale tests and fault rupture experiments. Contributions from trenchless technology are discussed. The development and validation of analytical models for the soil-structure interaction of these systems are also described. Lessons learned from the Kahramanmaras, Turkey earthquake are summarized with respect to ground deformation effects on underground infrastructure.

Prof.Tom O’Rourke

Thomas R Briggs Professor of Engineering Emeritus, Cornell University

Tom O’Rourke is the Thomas R. Briggs Professor of Engineering Emeritus in the School of Civil and Environmental Engineering at Cornell University. He is a member of the US National Academy of Engineering, Distinguished Member of ASCE, International Fellow of the Royal Academy of Engineering, Member of the Mexican Academy of Engineering, and a Fellow of the American Association for the Advancement of Science. He authored or co-authored over 430 technical publications, and has received numerous awards for his research. His research interests cover geotechnical engineering, earthquake engineering, underground construction technologies, engineering for large, geographically distributed systems, and geographic information technologies and database management.

Read More...2023-04-05 Webinar

Geotechnical Aspects of HDD Projects

Category: HDD

Presenter: Dan Lingenauber

Presenter: Dan Lingenauber

Date: 5 April 2023

Organization: TRACTO‑TECHNIK GMBH & CO. KG

Click to get access to video (Members Only)

Click to get access to video (Members Only)

Non-Members can join our webinars now (no fee required) but recorded videos and Presentation files are for ISTT members only (after member login). No certificates will be issued.

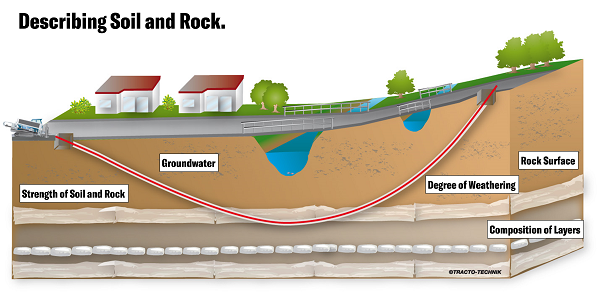

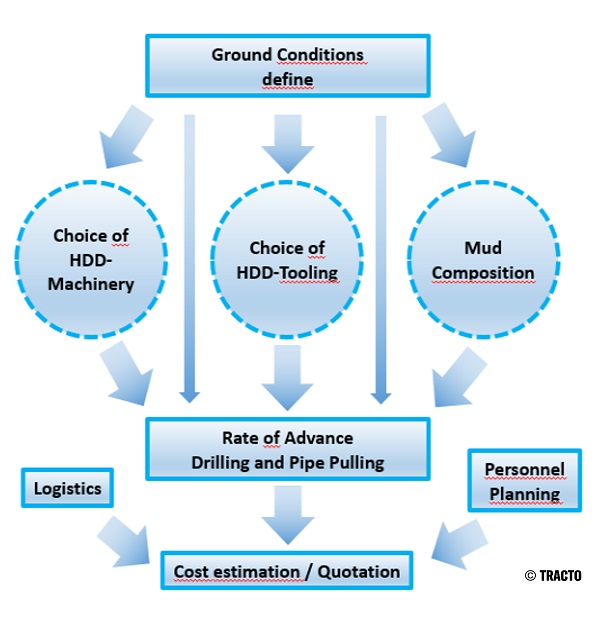

What are the most important ground parameters for HDD projects?

The significance of soil conditions for the success of HDD projects is emphasized repeatedly among experts and becomes obvious when problems occur on-site at the latest. But what are the key underground features, and how do you get a grip on them?

This webinar will give a short overview of the most important geotechnical aspects in HDD projects to illustrate the importance of soil and rock exploration in the planning stage.

The following topics will be covered:

- The most important parameters in soil and rock

- Exploration methods

- Describing and visualizing of underground conditions

Dan Lingenauber

GEOSERVICES, TRACTO‑TECHNIK GMBH & CO. KG

Mr. Dan Lingenauber has been a geotechnical engineer for 22 years with a background in open-pit lignite mining and geotechnical measurements in nuclear waste repository projects. He started in the HDD business working for TRACTO in 2019. TRACTO is a manufacturer of trenchless pipe-laying equipment based in Lennestadt, Germany, which has a worldwide distribution network. He consults customers especially involved in grid operators with geotechnical information.

Read More...

2023-02-15 Webinar

An Overview of Deterioration Mechanisms and Leakage Detection Techniques in Plastic Pipelines

Category: Condition Assessment

Presenter: Dr. Kalyan Piratla

Presenter: Dr. Kalyan Piratla

Date: 15 February 2023

Organization: Clemson University

Click to get access to video (Members Only)

Click to get access to video (Members Only)

Check your local time from worldtimebuddy.com

This webinar is open to Non-Members now (no fee required). Recorded videos and Presentation files are for ISTT members only (after member login). Updated on 13 Feb 2023.

Plastic pipe material is increasingly used for several applications including water, sewer, and gas. Plastic pipelines currently in service are not as old as the metallic pipelines, but there have been many seemingly premature failures warranting a comprehensive understanding of their failure mechanisms and how to keep track of them for appropriate intervention. Further, many condition assessment - specifically leakage detection - techniques that are suitable for metallic pipelines are not suitable for plastic. This presentation provides an overview of the deterioration mechanisms for plastic pipelines informed by the state-of-the-art literature. Additionally, it presents research insights into leakage detection in plastic pipelines. There have been numerous papers published on various aspects of plastic pipe degradation and leakage detection in multiple utility sectors, and this presentation synthesizes the most crucial knowledge out there for practical reference.

About Dr. Kalyan Piratla

Dr. Kalyan Piratla is an Associate Professor of Civil Engineering at Clemson University. His research work is focused on resilient planning and asset management aspects of buried pipeline infrastructure. He authored numerous peer-reviewed research articles and was recognized with awards such as the ASCE's Arthur M. Wellington prize, NASTT's Ralston Young Trenchless Achievement award, and Clemson University's Liles Professorship

Read More...

2022-06-30 Webinar

Soil friction and interaction during Microtunneling

Category: Microtunneling

Presenter: Wout Broere

Presenter: Wout Broere

Date: 30 June 2022

Organization: Delft University of Technology, The Netherlands

Click to get access to video (Members Only)

Click to get access to video (Members Only)

The friction forces on tunnel segments during pipe jacking determine to a large extent the capacity of the jacks and the number of intermediate jacking stations. Experience shows significant differences between predicted and actual friction forces. In this presentation we will look into the different factors that contribute to the overall soil friction and lead to the differences between design approaches and actual field experiences.

One of the major contributing factors to the overall friction is the boring of curves. To better understand the behaviour of the tunnel boring machine in curved alignments, a model has been developed, that takes the subgrade reaction and the stiffness of the soil into account. The subgrade reaction in the inner and outer curve of the TBM differs substantially and a reduction factor is introduced to deal with this effect. Especially in soft soils the impact of curved drives can be significant, and this will be illustrated by detailed measurements from several pipe jacking project in soft soil conditions.

◆About Wout Broere

Dr. Wout Broere is a professor of Underground Space Technology at Delft University of Technology, a board member for the Netherlands Society for Trenchless Technologies as well as a Fellow of the ISTT. His research interests range from trenchless technologies, large diameter tunnelling and the use of underground space to site investigation, physical modelling and offshore foundation engineering. He has extensively published on these topics and is currently editor-in-chief for the journal of Tunnelling and Underground Space Technology (incorporating Trenchless Technology Research).

Read More...2022-04-28 Webinar

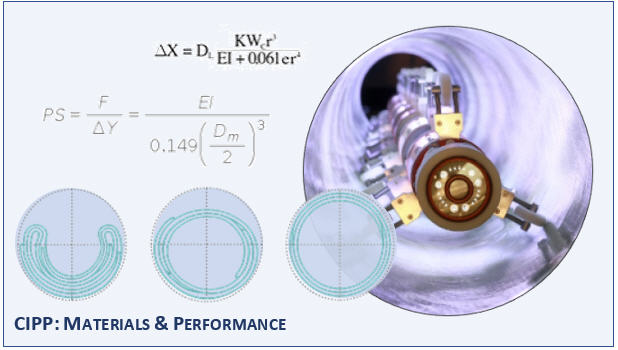

CIPP rehabilitation. Material and performance

Category: Rehabilitation

Presenter: Jan Borje Persson

Presenter: Jan Borje Persson

Date: 28 April 2022

Organization: JBP Composites S.L.

Click to get access to video (Members Only)

Click to get access to video (Members Only)

Since its introduction in the early 1970s CIPP has been one of the most frequently used trenchless technologies for rehabilitation of gravity pipe networks, and subsequently for pressurized pipes as well. From the early years, synthetic fibers were the material used as a carrier to the resin, in the manufacturing stage, until the uncured liner was installed and cured. The technical performance of the cured liner was dependent, in large part on the resin used.

During the 1980s a number of companies started to use more advanced materials which led to birth of reinforced CIPP. Material and the design of CIPP liners in both gravity and pressure applications have progressed especially during the last 20 years. Today we see structural CIPP applications in a large range of diameters and pipe shapes in many countries across the globe.

This webinar will look retrospectively at the development of both gravity and pressure CIPP applications, to give the audience an informed view as to what technical degree the technology for CIPP has evolved, in terms of materials, design and application technology, to achieve final pipe performance in meeting today’s requirements and relevant standards.

■ About Jan Borje Persson

After graduating as a computer hardware engineer in 1981, shortly afterward I began working in the thermoplastic industry while continuing studies in rubber and plastic at Lulea University. In 1985 I started to work with the technical development of the very first commercially produced UV cured fiberglass-reinforced liner system, for a Swedish-based company where I remained as a technical director and shareholder until 1999. Since 2004, I have founded and remain the major shareholder in a number of companies, within the JBP Group, with a focus on the trenchless sector. I am principal and Managing Director of JBP Composites and also Export Manager for BKP Berolina.

Read More...2022-02-08 Webinar

Design Methods for CIPP Liners in Gravity and Pressure Pipes - an Overview

Category: Rehabilitation

Presenter: Tom Sangster

Presenter: Tom Sangster

Date: 8 February 2022

Organization: Downley Consultants Ltd

Click to get access to video (Members Only)

Click to get access to video (Members Only)

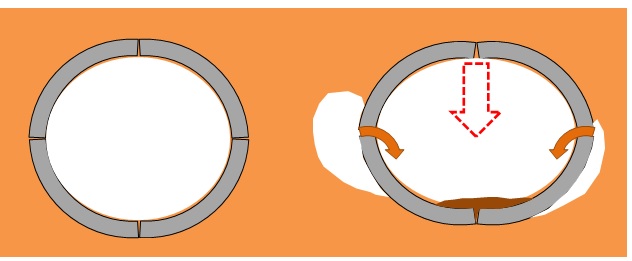

The design of CIPP liners in both gravity and pressure pipes has evolved significantly since the first somewhat empirical designs. There are now well-established methods for gravity pipe liners in the USA, the UK, Germany and France, to name but a few. These are evolving as more research and empirical evidence shows that the modified Glock method is more accurate than the Timoshenko method formerly used. France and Germany have already made the transition and the UK is doing so at present. The USA is expected to follow as well. In pressure pipes the situation is less clear and significant challenges remain in understanding the interactions between the liner and the host pipe. This webinar will review the design approaches for both gravity and pressure liners and will identify the key areas where more research and information is required, especially in the design of pressure pipe liners.

• About Tom Sangster

Tom Sangster is a professionally qualified Civil Engineer with 35 years of experience in geotechnical engineering and underground pipe networks and is Managing Director of Downley Consultants, an internationally renowned consulting engineer specializing in trenchless technology projects worldwide.

His experience in underground infrastructure encompasses inspection, assessment, and rehabilitation and in developing strategies for managing rehabilitation programs including risk management. He is a member of the Council of UKSTT and a past President of the Swiss Society for Trenchless Technology, CHSTT.

Read More...

2021-12-10 Webinar

On the Soil Behavior due to Rectangular Pipe Jacking

Category: Pipe jacking

Presenter: Prof. Hideki Shimada

Presenter: Prof. Hideki Shimada

Date: 10 December 2021

Organization: Kyushu University

Click to get access to video (Members Only)

Click to get access to video (Members Only)

The rectangular pipe has a higher utilization space comparing with the circular pipe, therefore, the rectangular pipe jacking has more potential applications for underground space excavation. However, ground response, jacking force, and pipe bearing state during rectangular pipe jacking are necessary to be analyzed before construction. In this presentation, four different rectangular pipe aspect ratios with the same utilization cross-section were investigated by using the 3D finite element method. In addition, till now, there is no generally accepted prediction equation for rectangular pipe jacking. It is suggested that the prediction equations of circular jacking will overestimate the jacking force for rectangular pipe jacking. Therefore, the modified prediction equation is established by considering the mechanism and behavior of the surrounding soil. In order to implement the specific phenomenon of friction force, the pipe-soil contact ratio λ is defined to evaluate the contact state, before being introduced to the modified friction force prediction equation. This modified friction force equation was verified and is applicable for the jacking force of rectangular pipe lacking.

◆About Prof.Hideki Shimada

Hideki Shimada, Professor of Department of Earth Resources Engineering, Kyushu University. He has published over 100 papers, and based on the citations report of 47 papers collected by Web of Science, the average H-index is 10 with 292 citations. He also published two books, and more than 20 scientific publications were in major international journals and top world conferences. He has achieved Academic Category Winner by International Society Trenchless Technology, No-Dig Award 2007 and 2013. He is now Vice-Chair of JSTT.

Read More...

2021-10-07 Webinar

Pipe rehabilitation with stainless steel sleeve

Category: Rehabilitation

Presenter: Christopher Rings and Mark André Haebler

Presenter: Christopher Rings and Mark André Haebler

Date: 7 October 2021

Organization: Uhrig Kanaltechnik GmbH

Click to get access to video (Members Only)

Click to get access to video (Members Only)

Pipe rehabilitation and repair with stainless steel sleeve is a purely mechanically installation system made of stainless steel and an EPDM compression seal for all common sewer, well, drinking water, and industrial pipes. The stainless-steel sleeve can be used for many different applications. Besides normal cracks, fragmented pipes, or in- & exfiltration you can also use it for root penetration or leaking joints. If the damage is longer than the sealing area of a single sleeve, it can be installed in serial as well.

How does it work?

The system seals and stabilizes the damage completely by mechanical, that means without any chemicals. Furthermore, the system is suitable for all common pipe materials (concrete, plastic and so on). The locking system – which is placed in the inside of the stainless-steel sleeve – ensures that the sleeve stays permanently in position. To expand the sleeve a special packer or special assembly tools are necessary. After the rehabilitation, the sleeve has its own static capability and absorbs the natural tectonic movements of the pipe.

And the WHY, we will explain during the presentation. This will not be a commercial webinar; we also reflect to the IKT report of partial repair and the DWA and EN standards.

◆About Christopher Rings

Mr. Christopher Rings is with Uhrig Kanaltechnik GmbH since October 2020. In his position, he is responsible for sales/support in the European market. Before he came to Uhrig, he worked 10 years for Vetter, a German manufacturer of Pipe Plugs where he gain valuable experience in the European trenchless technology market.

◆About Mark André Haebler (only for Q&A)

Mr.Mark André Haebler, MBA is with Uhrig Kanaltechnik GmbH since November 2017. In his position as Head of International Sales & Development, he is responsible for the world-wide sales, partner support and his team. Prior to his current position, he was part of the management team of Hermes Technologie GmbH, a German leader in trenchless support of manhole rehabilitation based on mortars and gouts. He is also vice president of the Austrian Association of Trenchless Technology and a member of the Board of Directors of the ISTT.

Read More...

2021-08-05 Webinar

Cured in Place materials and system quality assurance based around a performance specification and site evaluation

Category: Rehabilitation

Presenter: Ian Ramsay

Presenter: Ian Ramsay

Date: 5 August 2021

Organization: UKSTT - ViceChair

Click to get access to video (Members Only)

Click to get access to video (Members Only)

Cured in Place Pipelining (CIPP) has been around for circa. 50 years. Many thousands of kilometers have been installed successfully around the world since then. Standards such as ASTM and EN/DN have been developed to cover the quality, performance, and strength of the final product. CIPP is not suitable in every case for rehabilitation but is a valuable tool in the box of trenchless techniques.

Various different materials used in CIPP are available from a standard coated felt construction to reinforced layers. Resin technology has developed with various hybrid resins now available in addition to the standard polyester resins, whilst curing methods from ambient to hot water, steam, and UV/LED have also developed over the years.

Identifying the right system or choosing the right materials and processes can be very confusing when looking at a project.

In this webinar, we will explore the factors around the selection and specification of a CIPP solution which is fit for purpose. It will cover:

- Who can specify a CIPP solution

- How a performance specification is developed and executed.

- The key factors in the selection process of the materials and curing system.

We will also look at the project execution itself and QA/QC regarding the setup, time constraints, and various key factors to determine a successful installation and client handover.

◆ About Ian Ramsay

Ian has been involved in the trenchless market for over 25 years. Primarily around CIPP, both large and small diameter, he has worked throughout the world involved in project planning, specifications and material selection & supply. Ian is past chair of the UKSTT and is currently serving another term as vice-chair as well as being a board member of the ISTT.

Read More...

2021-06-23 Webinar

Repair of lateral sewers and lateral connections - comparison of techniques and quality assurance

Category: Rehabilitation

Presenter: Dr. Iain Naismith and Dipl.-Ing. Serdar Ulutaş

Presenter: Dr. Iain Naismith and Dipl.-Ing. Serdar Ulutaş

Date: 23 June 2021

Organization: IKT – Institute for Underground Infrastructure

Click to get access to video (Members Only)

Click to get access to video (Members Only)

This webinar highlights the lessons learned from 1:1 scale evaluation of the performance of technologies available for the repair of lateral sewers, particularly the use of patch repairs, and repair of lateral connections.

Smaller diameter lateral sewers which connect properties to main sewers are often in private ownership for at least part of their length, but sewer network owners may own all or part of them and/or be responsible for providing advice to property owners concerning their repair. Poor connections to main sewers are often a cause of groundwater ingress into sewer networks.

This webinar considers the findings from several large scale 1:1 comparative evaluations of the performance of different technologies for the repair of lateral sewers and lateral connections undertaken at IKT on behalf of German sewer network owners. These had a particular focus on the ability of products to stop groundwater infiltration and identifying quality assurance measures to be considered to ensure that installed solution will work effectively.

It will cover:

• Background to the issues

• Comparative evaluation of lateral connection repair technologies

• Repair of lateral sewers, particularly the use of patch repair

◆About: Dr. Iain Naismith

Dr Iain Naismith is a Senior Research Fellow at IKT with 35 years of experience in environmental, water and sewerage-related research. Based in the UK, he has a particular focus on international projects and knowledge sharing for this not-for-profit engineering research institute. He has been involved in the evaluation of performance of sewerage repair and rehabilitation products and products in contact with drinking water for some 20 years.

◆About: Dipl.-Ing. Serdar Ulutaş

MBA is a senior research fellow and head of the IKT Compare testing

programme for the comparative evaluation of technologies. In this role he is responsible for

recruiting sewer network operators for participation in comparative technology/product tests,

development of test concepts, construction of rigs and conducting evaluations.

2021-05-20 Webinar

Sewer Manhole Rehabilitation – quality assurance and comparison of techniques

Category: Rehabilitation

Presenter: Dr. Iain Naismith and Dipl.-Ing. Markus Gillar

Presenter: Dr. Iain Naismith and Dipl.-Ing. Markus Gillar

Date: 20 May 2021

Organization: Senior Research Fellows at IKT – Institute for Underground Infrastructure (Germany)

Click to get access to video (Members Only)

Click to get access to video (Members Only)

This webinar highlights the lessons learned from 1:1 scale evaluation of the performance of technologies available for the rehabilitated of manholes, with a particular focus on sealing against ground water infiltration.

The surcharging of sewer systems by groundwater impacts both their operation and that of the wastewater treatment works they connect to. Relining sewer pipes is part of the answer, but manhole shafts are also a significant pathway for infiltration.

This webinar explains the approach taken, at the request of German sewer network owners, to provide them with knowledge about performance and limits of manhole rehabilitation technologies and what quality assurance issues they need to be aware of. It will also signpost attendees to where this information is publicly available.

It will cover:

• Sewer manhole functions and the issues associated with them

• How IKT went about examining rehabilitation, defining damage patterns and reviewing the market

• What was discovered about the performance of rehabilitation techniques

• Key issues for applying QA to installations

2021-04-23 Webinar

Pipeline inspections and accurate information for no-dig process, Case in Finland

Category: Pipe inspection

Presenter: Tiia Lampola

Presenter: Tiia Lampola

Date: 23 April 2021

Organization: Riihimäki Water, Finland

Click to get access to video (Members Only)

Click to get access to video (Members Only)

The commonly used CCTV method is quite slow, e.g., due to the requirement of pre-cleaning (or -washing) of the pipelines. The process of choosing the parts of the water supply or sewer network for the inspection process is often also very vague and is made with too little information of the network. Pre-screening and analysis are often neglected or done only partly, which gives too little data for the proper and accurate process of pipeline inspections. See the full report from here.

The presented inspection methods and stages of the inspection process include:

· pre-screening methods

· requirements for the pre-cleaning (or -washing)

· CCTV and digital CCTV methods

· acoustic methods

· electrical and magnetic methods

· inspection methods for tunnels

· inspection methods for manholes

2021-03-25 Webinar

Considerations of Design and Construction for Horizontal Directional Drilling

Category: HDD

Presenter: Dr. Samuel Ariaratnam

Presenter: Dr. Samuel Ariaratnam

Date: 25 March 2021

Organization: Arizona State University

Click to get access to video (Members Only)

Click to get access to video (Members Only)

This presentation explores considerations of design and construction for HDD and offers insights into ways to increase project success. Technological advancements, design ingenuity, and construction innovations are all key elements that have led to increased adoption of this trenchless method.

Read More...2021-01-29 Webinar

Estimating the Jacking Forces for Pipejacking

Category: Microtunneling and Pipe Jacking

Presenter: Prof. Keh-Jian (Albert) Shou

Presenter: Prof. Keh-Jian (Albert) Shou

Date: 29 January 2021

Organization: ISTT vice-chair / National Chung-Hsing University, Taiwan

Click to get access to video (Members Only)

Click to get access to video (Members Only)

Among the others, pipejacking could be the most popular new installation trenchless methods. Jacking force is critical for a successful pipejacking, in which the control factors include overburden depth, frictional coefficient of soil-pipe interface, overcut, alignment, etc. Empirical formulas of jacking forces were reviewed. Comparisons on jacking forces with case studies were illustrated and discussed. New estimation method was also established and discussed.

Read More...2020-12-17 Webinar

A review of developments in UV Cured CIPP lining from its introduction in 1985

Category: Cured in Place Pipeliners

Presenter: Dr. Dec Downey

Presenter: Dr. Dec Downey

Date: 17 December 2020

Organization: Trenchless Opportunities Ltd

Click to get access to video (Members Only)

Click to get access to video (Members Only)

UV Curing for Cured in place pipelining was developed and launched in the UK and Sweden by Insituform Group and INPipe AB in the mid1980s. It took some time to establish but over the past twenty years has made a major contribution to the growth of CIPP worldwide. It offers certain advantages over more traditional curing methods but requires investment in technology, quality management, and skilled operators to take full advantage of its potential. This presentation will provide an appraisal of the technology and a glimpse at what the future may hold. (This webinar is available to ISTT members only.)

Read More...2020-11-18 Webinar

Environmental Impact Assessment of Steam-Cured Cured-in-Place Pipe (CIPP)

Category: Cured in Place Pipeliners

Presenter: Dr. John C. Matthews

Presenter: Dr. John C. Matthews

Date: 18 November 2020

Organization: Trenchless Technology Center (TTC) Director, Louisiana Tech University, Ruston, LA, USA

Click to get access to video (Members Only)

Click to get access to video (Members Only)

This presentation will discuss the findings from a recent study of the potential environmental impacts of steam-cured cured-in-place pipe (CIPP) installations. This comprehensive study collected real data from multiple projects using various sampling methods to determine the extent of any impacts. The objectives of the study were to both evaluate air emissions from steam-cured CIPP and determine potential impacts on workers. This was accomplished by directly measuring worker exposure to emissions for locations onsite or offsite. The installation sites represented a range of scenarios typical of CIPP installations. Dispersion of the emissions were modelled to estimate compound concentrations for a large set of scenarios and weather conditions. The potential health risks were evaluated based on appropriate health-based action levels using the measured and modeled data.

Read More... Cart

Cart